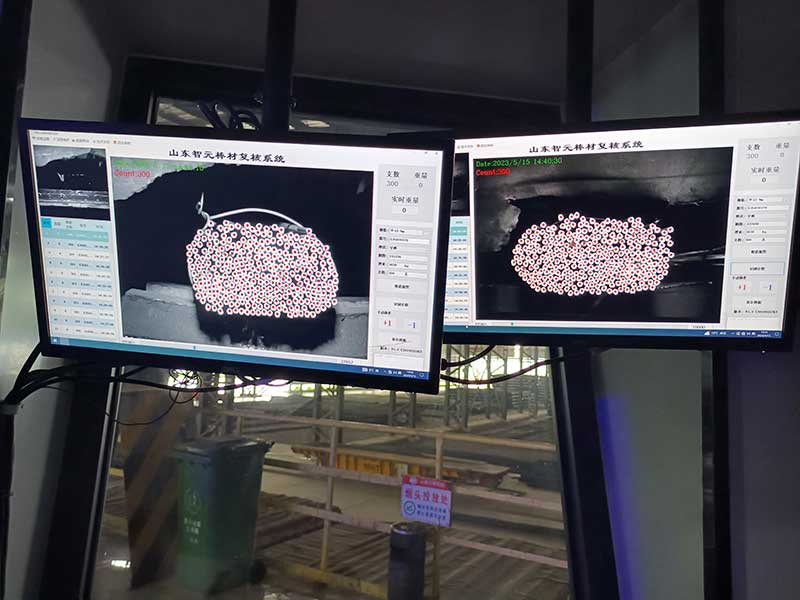

The main function of the high-precision bundled bar re inspection system is that when the bundled bar reaches the re inspection position, the system image sensor captures the end face image of the bundled bar. The system application software uses target recognition technology to recognize and analyze the picked up image, and then displays the calculated recognition result to the operator. When there is an error with the rated number of bundled bars, the system will give a real-time alarm prompt for manual re inspection, and at the same time, the system will generate and store the above information for future reference.

Technical indicators:

1) The review system is suitable for threaded steel with a diameter of 10-40mm; According to the number of bundles, the one-time accuracy rate of bundled bars is greater than or equal to 98% (without the need for manual intervention). The counting process of the system is manually participated in the metrological review, and the counting error is manually corrected to achieve a counting accuracy of 100%.

2) It has the function of transmitting data with the original weighing system and making weight judgments.

3) The system automatically generates daily and monthly report data for each shift. Each report contains data such as shift, time, bundle number, rated count per bundle, actual count, etc.

4) The image data storage size is six months of data, using a cyclic coverage method. The system can perform historical data queries based on logistics information such as bundle numbers.