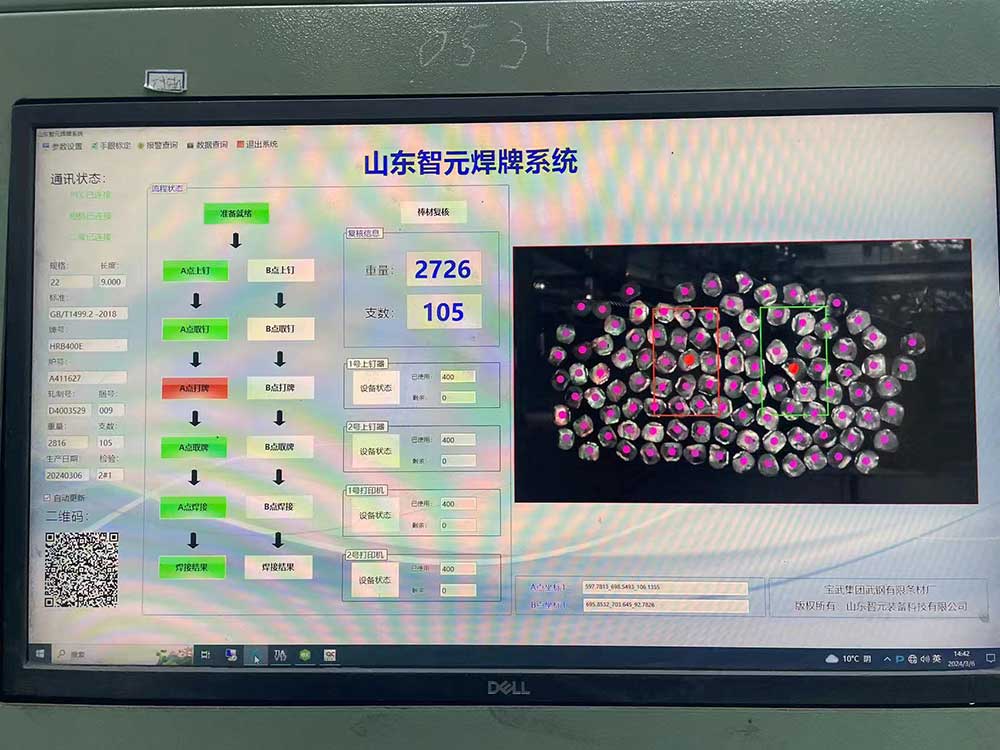

The automatic welding robot system consists of a robot system, an electrical control system, a vision system, a label printing system, a welding nail sorting system, etc., and achieves the following functional objectives.

1. Automatic printing and cutting of labels.

2. Automatic sorting and positioning of welding nails.

3. 3D vision system inspection of steel bundle bar end faces.

4. Automatic welding, automatic judgment, and repair welding of two labels on the same end face.

5. Integrate with on-site MES system and measurement system communication to achieve printing data transmission.

6. Interlock with on-site production safety to ensure stable and reliable production on site.

Technical indicators:

1) The success rate of one-time welding is ≥ 99.8%;

2) The completion time for welding 2 cards is ≤ 25 seconds;

3) The success rate of visual system photography is 100%;

4) The accuracy rate of one-time re inspection of steel bundle count is ≥ 99%.